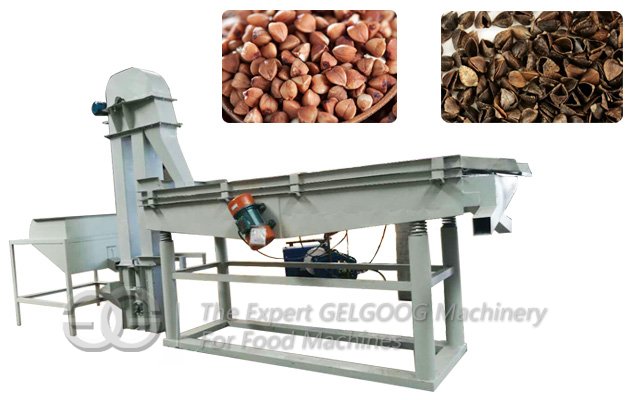

Buckwheat Cleaning And Hulling Line Manufacturer

| MOQ: | 1 /Sets |

| Brand: | GELGOOG |

| Certification: | CE |

| Supply Ability: | 200 Set/Sets Per Month |

| PAY METHOD: | WEST UNION L/C T/T CASH |

| Warranty Time: | 12 Months |

| LOADING PORT: | Shanghai/Qingdao |

| Country Of Origin: | China |

Features

Buckwheat Cleaning And Hulling Line Is Divided Into Three Parts:

1. Raw buckwheat grain cleaning and grading.

2. Buckwheat shelling and cleaning.

3. Buckwheat hull cleaning, grading packaging.

Major Equipment of Buckwheat Hulling Processing Line:

First, clean up the buckwheat raw materials. In this section, the buckwheat raw materials are cleaned to remove the impurities in the raw grains (including small grain materials that cannot be processed), properly moistened and stored, and the buckwheat raw grains are divided into six grades.

Second, buckwheat shelling and cleaning. After grading the raw materials in this section, the shelling process is separately performed, and the buckwheat granules are processed to meet the requirements.

Third, the processed buckwheat hulls are cleaned to remove various impurities including unhulled buckwheat, buckwheat, etc., and separate and complete buckwheat hulls are separated by grading screen according to customer requirements to improve the economic value of the buckwheat husks.

Advantages:

Advantages:

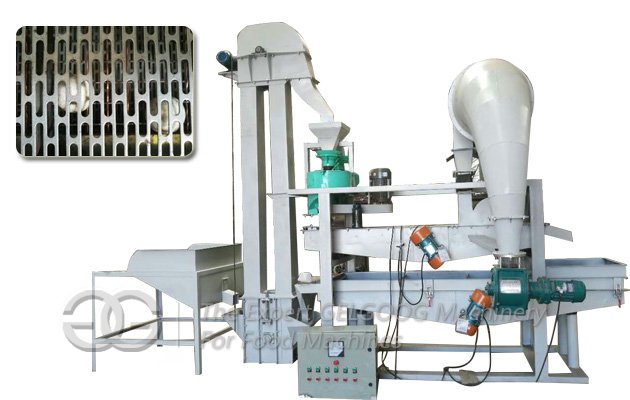

The buckwheat shelling production line consists of feeding hopper, raw material elevator, sheller machine, separating screen and sorting machine for kernel and shell, leaf spring screen, collecting hopper, electric controlling cabinet.

It has the characteristics of reasonable design, beautiful appearance, compact structure, stable performance, high yield, simple operation and maintenance. Our company can provide one-stop service of process design, production and installation, equipment commissioning, personnel training and normal production according to the customer's actual needs and site.

Technical Data

| Processing technician | Machine | Quantity | Capacity |

|

Dehuller Unit |

Input Hopper | 2 | 400KG/H |

| Elevator | 2 | ||

| Dehuller | 2 | ||

| Sorting sieve section | 4 | ||

| control cabinet | 1 | ||

|

Cleaning&Grading |

Input Hopper | 1 |

800-1000kg/H |

| Elevator | 1 | ||

| Multifunctional impurity remover | 1 | ||

| bucket elevator | 1 | ||

| classification unit | 3 | ||

| control cabinet | 1 |

FAQ

1.What is the usage of this buckwheat shelling production line?

-- It can peel different size of cashew, product meets the health standard.

2. What is the voltage/phase for this machine?

-- We normally make voltage into 220V/50HZ/Single phase or 380V/50HZ/Three Phase. But it can be made according to clients' demand, like 110V/60HZ/Three phase and so on.

3. What kind of packing box is?

-- We pack machines in a standard exporting plywood case, no vermin, germs.It can help get better protection while transporting.

4. How long is the guarantee?

-- We promise guarantee as half of one year for non-human damage factor.

5. How should I do if meet some trouble while using?

-- Don't worry about that. We are always be pleased to provide using support to clients. We can take a video for showing how to resolve the problem, and write detail resolution to you.

6. What's the payment mode?

-- T/T, L/C, Western Union or Money Gram.