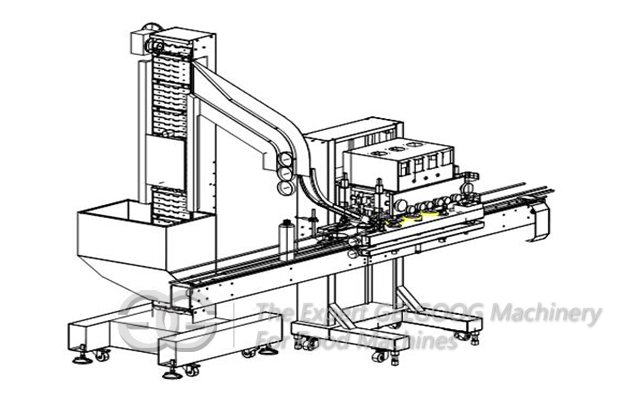

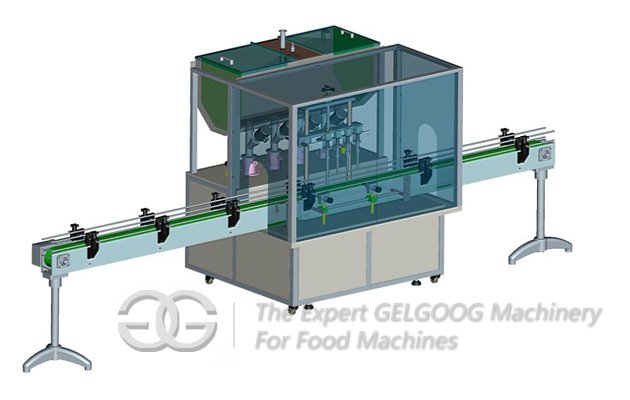

Automatic Peanut Butter Filling and Capping Machine

| MOQ: | 1 /Sets |

| Brand: | GELGOOG |

| Certification: | CE |

| Supply Ability: | 200 Set/Sets Per Month |

| PAY METHOD: | WEST UNION L/C T/T CASH |

| Warranty Time: | 12 Months |

| LOADING PORT: | Shanghai/Qingdao |

| Country Of Origin: | China |

Features

Introduction:

The equipment has good appearance, reasonable structure, according to customer requirements, it can install programmable control (PLC), touch screen operation interface to a high degree of automation. the operation is simple and flexible, the use is convenient and safe. Less investment, high efficiency, stability, good ideal choice. It specially is used for filling the paste, such as the peanut butter, sesame butter and so on. It can fill the butter automatically. This one is the four heads machine which has a bigger capacity, we also can customize other capacity according to customer’s demands. The machine is made of stainless steel and is used for food completely. This machine also have the automatic conveying function. You can match this machine with other machine, such as the capping machine, also can use it in production line. No need manual operation, save the cost, high efficiency.

Advantage:

Servo filling machine Main features: stainless steel, servo motor control, can filling 15-1000ML any capacity, fast filling, pour bottle, no bottle no filling. Filling speed can be adjusted, to overcome the traditional slow filling characteristics, from filling machine is no longer in a head count to calculate yield. The machine does not adjust node, as long as the input speed and a single bottle milliliters, you can directly filling. Fast easy to use, non-drip.

Technical Data

| Model | GG-4 |

| Capacity | 20-50 bottles/min |

| Filling Volume | 15-1000ml |

| Accuracy | 1% |

| Voltage | 220V 50HZ |

| Weight | 550kg |

| Dimension | 3000*1500*2200mm |

FAQ

1.What is the usage of this machine?

-- used for filling, sealing, labeling and other equipment of automatic packaging production line machinery

2. What is the voltage/phase for this machine?

-- We normally make voltage into 220V/50HZ/Single phase or 380V/50HZ/Three Phase. But it can be made according to clients' demand, like 110V/60HZ/Three phase and so on.

3. What kind of packing box is?

-- We pack machines in a standard exporting plywood case, no vermin, germs.It can help get better protection while transporting.

4. How long is the guarantee?

-- We promise guarantee as half of one year for non-human damage factor.

5. How should I do if meet some trouble while using?

-- Don't worry about that. We are always be pleased to provide using support to clients. We can take a video for showing how to resolve the problem, and write detail resolution to you.

6. What's the payment mode?

-- T/T, L/C, Western Union or Money Gram.