Buckwheat Cleaning And Hulling Line Manufacturer

Brand:GELGOOG MACHINERY

Certification: CE

Pay Method: WEST UNION L/C T/T CASH

Warranty Time: 12 Months

Loading Port: Shanghai/Qingdao

Country Of Origin: China

Details:

Buckwheat Cleaning And Hulling Line Is Divided Into Three Parts:

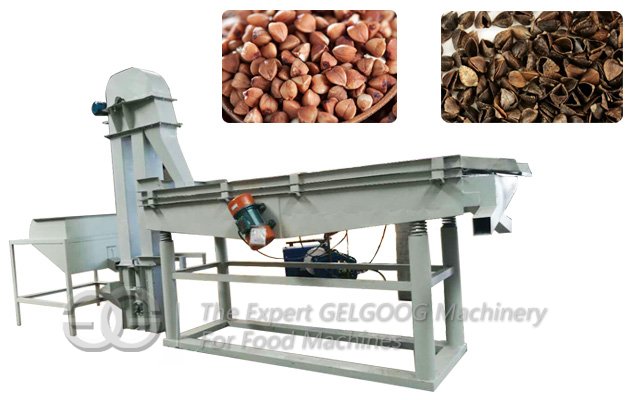

1. Raw buckwheat grain cleaning and grading.

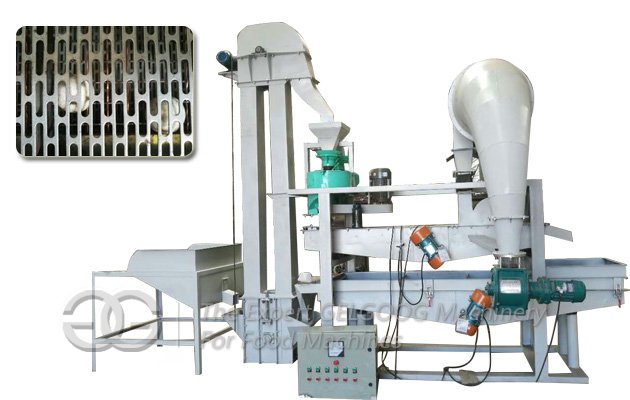

2. Buckwheat shelling and cleaning.

3. Buckwheat hull cleaning, grading packaging.

Major Equipment of Buckwheat Hulling Processing Line:

First, clean up the buckwheat raw materials. In this section, the buckwheat raw materials are cleaned to remove the impurities in the raw grains (including small grain materials that cannot be processed), properly moistened and stored, and the buckwheat raw grains are divided into six grades.

Second, buckwheat shelling and cleaning. After grading the raw materials in this section, the shelling process is separately performed, and the buckwheat granules are processed to meet the requirements.

Third, the processed buckwheat hulls are cleaned to remove various impurities including unhulled buckwheat, buckwheat, etc., and separate and complete buckwheat hulls are separated by grading screen according to customer requirements to improve the economic value of the buckwheat husks.

Advantages:

Advantages:

The buckwheat shelling production line consists of feeding hopper, raw material elevator, sheller machine, separating screen and sorting machine for kernel and shell, leaf spring screen, collecting hopper, electric controlling cabinet.

It has the characteristics of reasonable design, beautiful appearance, compact structure, stable performance, high yield, simple operation and maintenance. Our company can provide one-stop service of process design, production and installation, equipment commissioning, personnel training and normal production according to the customer's actual needs and site.

Technical Data:

| Processing technician | Machine | Quantity | Capacity |

|

Dehuller Unit |

Input Hopper | 2 | 400KG/H |

| Elevator | 2 | ||

| Dehuller | 2 | ||

| Sorting sieve section | 4 | ||

| control cabinet | 1 | ||

|

Cleaning&Grading |

Input Hopper | 1 |

800-1000kg/H |

| Elevator | 1 | ||

| Multifunctional impurity remover | 1 | ||

| bucket elevator | 1 | ||

| classification unit | 3 | ||

| control cabinet | 1 |

Leave a Comment:

Small Scale Peanut Butter Manufacturing Plant In India

Peanut butter on the market today is made from a specialized peanut butter manufa

24/08/18Read More

How to Remove Black Gram Bean Skin Easily ?

Black gram beanis a legume grown in India and has many good health benefits. Itca

31/07/18Read More

Four Steps Get the Skins Off of Peanut

If you want to get the skins of peanut ,how do you get the skins off of peanuts?

27/07/18Read More

Automatic Coffee Roasting Machine Design

Do you know the cocoa roasting machine design ? there will show you something abo

18/07/18Read More