Gas Continuous Nuts/Pig Skin Frying Machine with Oil Filtering Function

Brand:GELGOOG MACHINERY

Certification: CE

Pay Method: WEST UNION L/C T/T CASH

Warranty Time: 12 Months

Loading Port: Shanghai/Qingdao

Country Of Origin: China

Details:

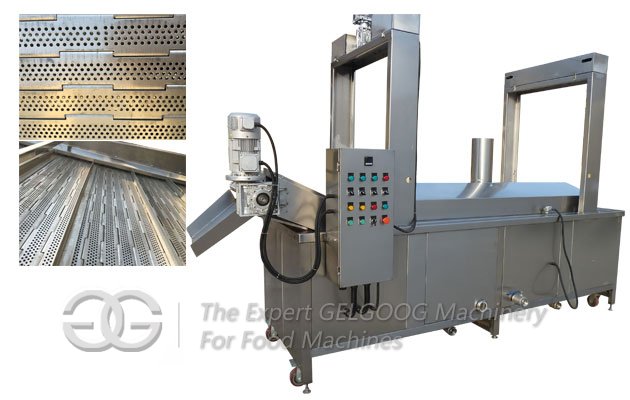

Introduction for Continuous Fryer Machine

Mesh belt continuous pig skin fryer machine, full stainless steel material, adopts advanced technology for oil and water mixture, overcome the defect of conventional frying machine. Automatic filtration can keep the oil clean, make fried product consistent, can not only improve the product quality, prolong the shelf life, and brought higher value-added products. Oil temperature, water temperature automatic control, can always maintain good working condition, not only increase the production but also can make the product quality stable, with nice color and aroma. The machine automatic filtering system can greatly prolong the service life of frying oil, no oil change frequently, high fuel efficiency.

Mesh belt continuous pig skin fryer machine, full stainless steel material, adopts advanced technology for oil and water mixture, overcome the defect of conventional frying machine. Automatic filtration can keep the oil clean, make fried product consistent, can not only improve the product quality, prolong the shelf life, and brought higher value-added products. Oil temperature, water temperature automatic control, can always maintain good working condition, not only increase the production but also can make the product quality stable, with nice color and aroma. The machine automatic filtering system can greatly prolong the service life of frying oil, no oil change frequently, high fuel efficiency.

Features of Continuous Fryer Machine for Corn Chips

1. A kind of belt fryer,suitable for different material, such as French fries, potato chips, peanuts, broas beans, cashew nuts, pork rinds, chinchin, corn chips, corn flakes, etc

2. Realize the frying continuous and automatically.

3. This machine is key machine during fried pork skin frying line, it receipts blanching peanuts, bring them to heated oil, during frying, the peanuts will stay on the belt and be fried evenly within short time.

3. Due to speed of conveyor is specified, peanut will stay in oil pan with same time. Fried peanuts can keep uniform color and same taste.

4. This fryer has heat prevention layer, in order to keep temperature of oil in same temperature, meanwhile, it also prevent heat loss, increase the heat energy utilization.

5. Continuous fryer machine is matched with advanced oil filtering system to keep the oil clean all the time, this system guarantee the fried peanut with glazed and pretty color.

6. This machine can be designed in electrical or gas to be heated, it is an ideal machinery for modern industrial food factory.

Advantage of Continuous Pig Skin Fryer Machine

It is used for frying nuts,beans,cashew,peanuts. The frying line includes feeding machine--frying machine--de-oiling machine--de-oiling output conveyor--flavoring machine--flouring output conveyor--packing machine

It can filter the dregs automatically and also can be equipped with frying circulation-filtering system

Convenience washing 1.World-famous Brand Electronic Apparatus ensure the Excellent and Stable Performance.

Controller Box made of Stainless Steel or Sprayed-plastic(optional), Allows adjust Frying Time by Variable Conveying Speed as required, Alarm Oil Level.

Double Layer 304 Stainless Steel Belt, Preventing Products Floating, Ensure Complete and Perfect Frying Effect.

Scrapers fixed on the belt, Make the products come out easily. The machine can be used with production line of attachment, feed on the other side of the material. The synchronous control and reduce the incidence of adverse;

This machine also used for frying Chin Chin.

Technical Data:

| Model |

GG-4000 (Electric) |

GG-4000 (Gas) |

| Power | 120kw | 2.25kw |

| Dimension | 4000*1200*2400mm | 4000*1800*2400mm |

| Capacity | 200-500kg/h | 200-500kg/h |

| Weight | 900kg | 1400kg |

Leave message for price:

Small Scale Peanut Butter Manufacturing Plant In India

Peanut butter on the market today is made from a specialized peanut butter manufa

02/01/20Read More

Chilli Processing Machines Sold To India

On October 8th, our chili processing machine will be sold to India . 1 unit of mi

10/10/19Read More

How to Remove Black Gram Bean Skin Easily ?

Black gram beanis a legume grown in India and has many good health benefits. Itca

31/07/18Read More

Four Steps Get the Skins Off of Peanut

If you want to get the skins of peanut ,how do you get the skins off of peanuts?

27/07/18Read More