What Are The Common Failures of Peanut Peeler?

11/02/18Cara

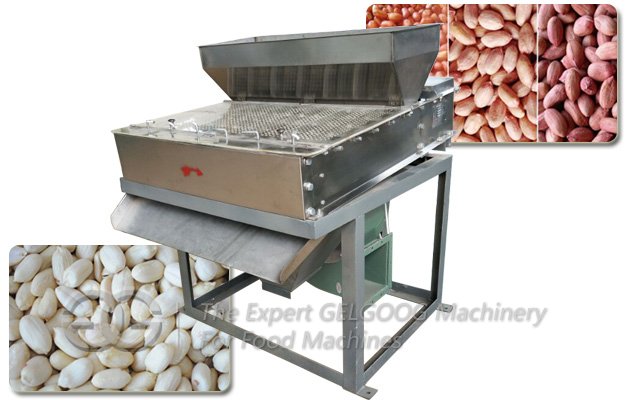

Peanut peeling machine is the most common peanut processing machinery, if used improperly or do not pay attention to maintenance, over time there will be some failure, do you know what are the common failures of peanut peeler?

In the course of using the peanut skin if found back to the material, the wind turbine windshield should be adjusted to increase the amount of air intake. Conversely, if found in the peanut skin outside the machine containing peanuts and more, should be adjusted into the small amount of air, there are baffles out of the skin, you can increase or decrease, in order to obtain satisfactory results.

If the use of high rate of crushing, should be resolved from two aspects, one is to adjust the gap between the drum and the bottom of the screen, the general first 38-40mm warehouse, the second warehouse 22-25mm is appropriate (the new machine has been in the plant Tune good); Second, replace the large gap at the end of the sieve.

Peanut peeling machine fixed installation must be maintained around the level (according to the flow of peanuts to judge), otherwise there will be mixed peanut exports and peanut phenomenon. Leveling method is: more side of peanut said low, the use of wood or sack to paddle the wheel here; small peanuts on the side that high, should reduce the pad below the wheels to the net Ren appropriate; small fruit export if the inclusion of nuts that end of this partial, steering wheel pad should be high.

In accordance with the above method, when we operate the peanut peeling machine if you encounter some minor problems, then we can rely on their own to solve these glitches, of course, in the maintenance process should pay attention to safety, if you are interested in our roasted peanut peeling machine, please feel free to contact me.

Contacts: Cara

Email|Skype: leo@machinehall.com

Contacts: Cara

Email|Skype: leo@machinehall.com

Leave message for price: